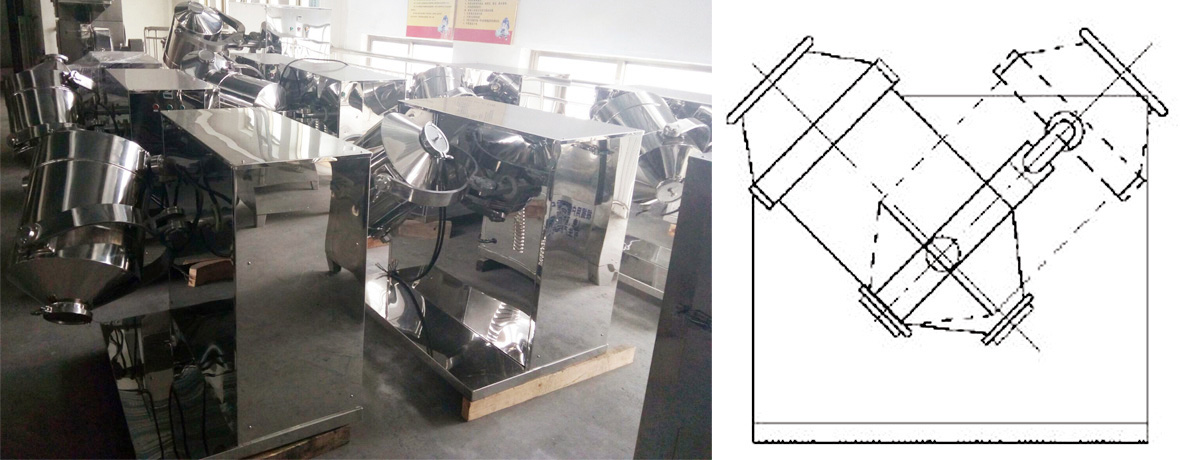

3D Mixer

Main Application:

This 3D mixer is suitable for phamaceutical, chemical, food, light industry, electronics, mining and metallurgy, national defense industry and the research units of powder, granular material mixed with high uniformity.

Working Principles:

This 3D mixer is composed by the base, speed motor, shaft, rotary connecting rod and cylinder components. Axis of the cylinder charge in the active movement, led mainly as flat rock, and complex movement, which makes the material for the ring along the cylinder, radial and axial movement of the three to the compound to achieve the mutual flow of proliferation of a variety of materials, doping, in order to achieve the purpose of mixing with high uniformity. This 3D mixer is a sterile, clean, energy-effcient completely closed mixer.

Feature:

The material in the mixed without the role of centrifugal force and proportion of segregation and layered, accumulation phenomenon. 3D mixer movement mixer use of unique three degrees of movement, the translation of the rotation and rock principle, produce a shares fo alternating power pulse dyke movement, continuously promote mixed materials, the produce of the eddy current with varying energy gradient, and that can produce great mixed effect. This 3D mixer also has smooth running, low noise, hight coefficient of load time is short, mixing the advantages of this machine is composed of the engin, transmission system, electric contrl system, learn a lot from the agency. Because mix barrel has many of the direction of movement, make the body materil mixing barrel coss PM, the mixing effect is high, the evenness of 99.9% above the biggest load coefficient 0.9 (ordinary mixer for 0.4-0.6). mix of short time, high efficiency. The 3D mixer mixing barrel shape design is unique, the barrel body wall after fine polishing, no dead angle, no pollution materials, the material is convenient. It is easy washing, simple operation, etc.

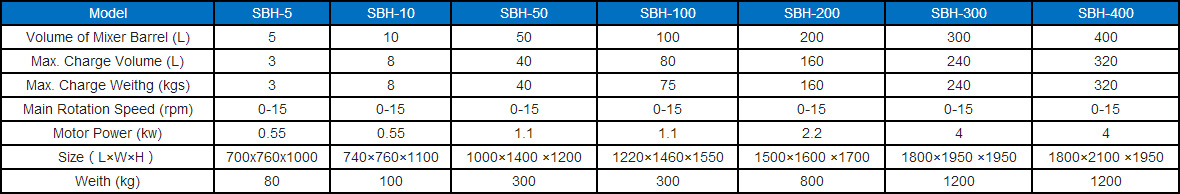

Technical Specificaiton: