Turbine Pulveriger

Main Application:

This turbine pulveriger mainly used in pharmaceutical, chemical, food ( such as: griger, chilli, peper, oil and wheat, soybean, vegetables) in the crushing process low hardness, fineness of 30-150 mesh adjusted between high output yield, fine grain size, low noise, low energy consumption, simple maintenance, and easy to intall, especially for oily, viscous, heat-sensitive, fibrous materials such as low hardness crushing process.

Working Principles:

1. structure: main chassis, the door, turbine, shaft, screen, pulleys and motors and otaher component parts.

2. the working principles: shift turbo mill, the motor drive shaft and the turbine high-speed rotation. Ring on the turbine and screen borken grinding blocks, grinding vice, when the material from the hopper into the machine in the cavity, the material flow in the turbine rotating in the closely to friction and impact strongly on the inside of the turbine blades, and leaves the gap between the block and mill grinding again. In the crushed material, while absorbing large quantities of air turbine, which played a cooling air machine, grinding materials and the role of transmission fines. Materials depends on the fineness of grinding nature of the materials and screeen size, and the materials and the air throughtput.

Turbine pulveriger bearing components with a special seal, can effectively prevent dust entering the bearing cavity, thus extending bearing life. Equipped with a sllicon rubber gasket inside the door, no dust leakage and pollution of the operating environment.

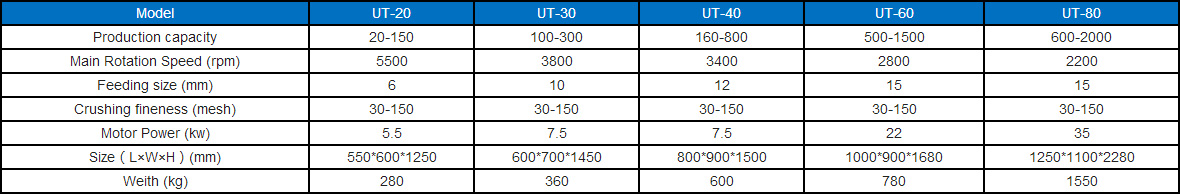

Technical Specificaiton: